New Technologies. New Possibilities.

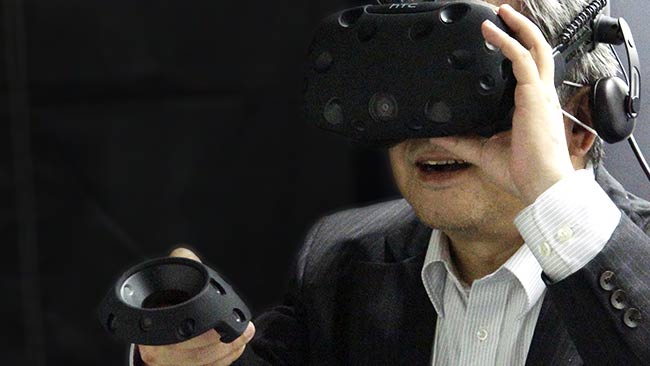

People often talk about virtual reality and augmented in the same breath as if they are merely different shades of the same shiny technology wonder. In fact, virtual reality and augmented reality are very different ideas and very different technologies. But when it comes to serving the needs of engineers and manufacturing professionals, VR and AR are complimentary technologies, opposites sides of the same coin.

The design of a production line creates a complex design. There exist many dependencies within production stations and between production stations. How can the design engineers and the manufacturing engineers check the design and prepare for its implementation most effectively?

Augmented reality is the compliment to virtual reality for the engineering and manufacturing teams. After verifying and practicing the production line construction in VR, the implementation teams benefit from AR in the actual implementation.

Now, the teams are in the actual factory. The implementation is in progress. Using AR, the entire design and assembly information is available visually and in context. Need to verify the cable routing between production stations? Augmented reality technology is your digital assistant. Need to contact an expert for a problem on the line? Bring the expert online, live on the production floor via AR.

The same complimentary cycle of VR and AR in manufacturing applies throughout the production lifetime as the production line is modified, updated, and maintained. With verification and training in virtual reality, documentation and design data on site using augmented reality, the process of maintaining a production system can be done more reliably, faster, and with fewer surprises.

These complimentary technologies save time, save money, and avoid cost and schedule overruns.